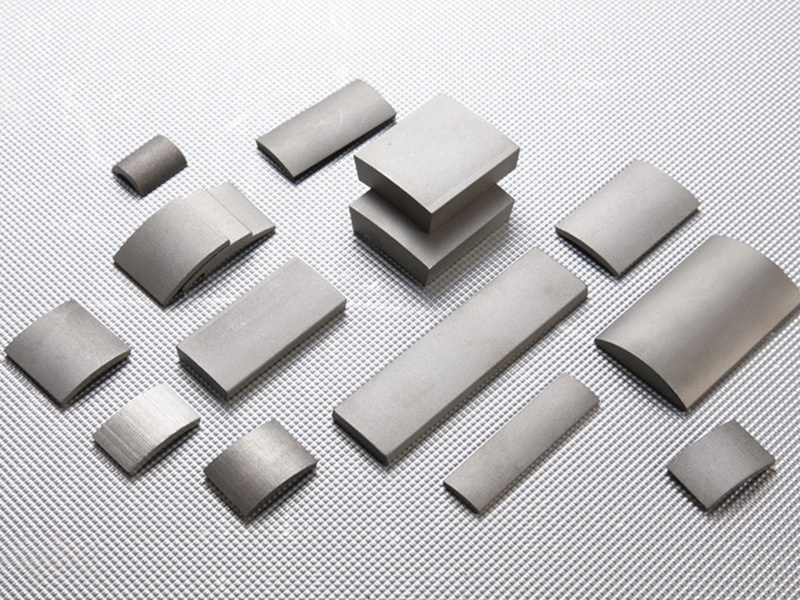

Samarium cobalt permanent magnets can be divided into two categories, SmCo5 and Sm2Co17. According to the composition, SmCo5 is the first-generation rare earth permanent magnet materials, while Sm2Co17 is the second-generation. Its main features are high magnetic properties, good temperature resistance, and great corrosion resistance.