| Grade | Remanence | Intrinic Coercivity | Coercivity | Max Energy Product | Density | recoil permeability | Temperature Coefficient | Max Working Temperature | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | αBr | αHcj | ℃(L/D=0.7) | ||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | %/℃ | %/℃ | |||

| N56 | 1.51 | 1.47 | 15.1 | 14.7 | 876 | 11 | 836 | 10.5 | 454 | 414 | 57 | 52 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N54 | 1.49 | 1.45 | 14.9 | 14.5 | 955 | 12 | 836 | 10.5 | 437 | 406 | 55 | 51 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N52 | 1.46 | 1.42 | 14.6 | 14.2 | 955 | 12 | 836 | 10.5 | 422 | 390 | 53 | 49 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N50 | 1.44 | 1.39 | 14.4 | 13.9 | 955 | 12 | 860 | 10.8 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N48 | 1.43 | 1.37 | 14.3 | 13.7 | 955 | 12 | 860 | 10.8 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N45 | 1.37 | 1.32 | 13.7 | 13.2 | 955 | 12 | 860 | 10.8 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N42 | 1.32 | 1.28 | 13.2 | 12.8 | 955 | 12 | 860 | 10.8 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N40 | 1.28 | 1.25 | 12.8 | 12.5 | 955 | 12 | 860 | 10.8 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N38 | 1.25 | 1.22 | 12.5 | 12.2 | 955 | 12 | 860 | 10.8 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N35 | 1.22 | 1.17 | 12.2 | 11.7 | 955 | 12 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N33 | 1.17 | 1.13 | 11.7 | 11.3 | 955 | 12 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| N30 | 1.13 | 1.08 | 11.3 | 10.8 | 955 | 12 | 796 | 10.0 | 247 | 223 | 31 | 28 | 7.50 | 1.05 | -0.12 | -0.76 | 80 |

| 56M | 1.50 | 1.46 | 15.0 | 14.6 | 1035 | 14 | 995 | 12.5 | 446 | 406 | 56 | 51 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 54M | 1.49 | 1.44 | 14.9 | 14.4 | 1114 | 14 | 1035 | 13.0 | 438 | 398 | 55 | 50 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 52M | 1.46 | 1.42 | 14.6 | 14.2 | 1114 | 14 | 1035 | 13.0 | 422 | 382 | 53 | 48 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 50M | 1.44 | 1.39 | 14.4 | 13.9 | 1114 | 14 | 1035 | 13.0 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 48M | 1.42 | 1.37 | 14.2 | 13.7 | 1114 | 14 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 45M | 1.37 | 1.32 | 13.7 | 13.2 | 1114 | 14 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 42M | 1.32 | 1.28 | 13.2 | 12.8 | 1114 | 14 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 40M | 1.28 | 1.25 | 12.8 | 12.5 | 1114 | 14 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 38M | 1.25 | 1.22 | 12.5 | 12.2 | 1114 | 14 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 35M | 1.22 | 1.17 | 12.2 | 11.7 | 1114 | 14 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 33M | 1.17 | 1.13 | 11.7 | 11.3 | 1114 | 14 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 30M | 1.13 | 1.08 | 11.3 | 10.8 | 1114 | 14 | 796 | 10.0 | 247 | 223 | 31 | 28 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| 52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1059 | 13.3 | 422 | 382 | 53 | 48 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 48H | 1.42 | 1.36 | 14.2 | 13.6 | 1353 | 17 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 45H | 1.37 | 1.32 | 13.7 | 13.2 | 1353 | 17 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 42H | 1.32 | 1.28 | 13.2 | 12.8 | 1353 | 17 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 40H | 1.28 | 1.25 | 12.8 | 12.5 | 1353 | 17 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 38H | 1.25 | 1.22 | 12.5 | 12.2 | 1353 | 17 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 35H | 1.22 | 1.17 | 12.2 | 11.7 | 1353 | 17 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 33H | 1.17 | 1.13 | 11.7 | 11.3 | 1353 | 17 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 30H | 1.13 | 1.08 | 11.3 | 10.8 | 1353 | 17 | 796 | 10 | 247 | 223 | 31 | 28 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| 50SH | 1.42 | 1.39 | 14.2 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 48SH | 1.40 | 1.36 | 14.0 | 13.6 | 1592 | 20 | 1035 | 13.0 | 390 | 358 | 49 | 45 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 939 | 11.8 | 326 | 302 | 41 | 38 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 876 | 11.0 | 287 | 263 | 36 | 33 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| 33SH | 1.17 | 1.13 | 11.7 | 11.3 | 1592 | 20 | 844 | 10.6 | 271 | 247 | 34 | 31 | 7.40 | 1.04 | -0.115 | -0.56 | 150 |

| 30SH | 1.13 | 1.08 | 11.3 | 10.8 | 1592 | 20 | 804 | 10.1 | 247 | 223 | 31 | 28 | 7.40 | 1.04 | -0.115 | -0.56 | 150 |

| 48SHT | 1.40 | 1.36 | 14 | 13.6 | 1751 | 22 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 45SHT | 1.37 | 1.32 | 13.7 | 13.2 | 1751 | 22 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 42SHT | 1.32 | 1.28 | 13.2 | 12.8 | 1751 | 22 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 40SHT | 1.28 | 1.25 | 12.8 | 12.5 | 1751 | 22 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 38SHT | 1.25 | 1.22 | 12.5 | 12.2 | 1751 | 22 | 923 | 11.6 | 310 | 287 | 39 | 36 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 35SHT | 1.22 | 1.17 | 12.2 | 11.7 | 1751 | 22 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| 33SHT | 1.17 | 1.13 | 11.7 | 11.3 | 1751 | 22 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.40 | 1.04 | -0.115 | -0.53 | 160 |

| 30SHT | 1.13 | 1.08 | 11.3 | 10.8 | 1751 | 22 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.40 | 1.04 | -0.115 | -0.53 | 160 |

| 45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| 45UHT | 1.36 | 1.32 | 13.6 | 13.2 | 2149 | 27 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 42UHT | 1.32 | 1.28 | 13.2 | 12.8 | 2149 | 27 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 40UHT | 1.28 | 1.25 | 12.8 | 12.5 | 2149 | 27 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 38UHT | 1.25 | 1.22 | 12.5 | 12.2 | 2149 | 27 | 923 | 11.6 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 35UHT | 1.22 | 1.17 | 12.2 | 11.7 | 2149 | 27 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 33UHT | 1.17 | 1.13 | 11.7 | 11.3 | 2149 | 27 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 30UHT | 1.13 | 1.08 | 11.3 | 10.8 | 2149 | 27 | 852 | 10.7 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| 42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| 40EHT | 1.28 | 1.25 | 12.8 | 12.5 | 2547 | 32 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| 38EHT | 1.25 | 1.22 | 12.5 | 12.2 | 2547 | 32 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| 35EHT | 1.22 | 1.17 | 12.2 | 11.7 | 2547 | 32 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| 33EHT | 1.17 | 1.13 | 11.7 | 11.3 | 2547 | 32 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| 30EHT | 1.13 | 1.08 | 11.3 | 10.8 | 2547 | 32 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| 38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| 35AH | 1.20 | 1.17 | 12.0 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| 33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| 30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| 28AH | 1.09 | 1.02 | 10.9 | 10.2 | 2786 | 35 | 772 | 9.7 | 231 | 199 | 29 | 25 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| 35TH | 1.22 | 1.17 | 12.2 | 11.7 | 3182 | 40 | 867 | 10.9 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

| 33TH | 1.17 | 1.11 | 11.7 | 11.1 | 3182 | 40 | 851 | 10.7 | 271 | 239 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

| 30TH | 1.13 | 1.08 | 11.3 | 10.8 | 3182 | 40 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

Note:Temperature Coefficient calucalated by temperature range:Hcj<20kOe,ΔT:20-100℃;Hcj≥20kOe,ΔT:20-150℃,Please contact our sales staff for more demagnetization curve.

| Grade | Remanence | Intrinic Coercivity | Coercivity | Max Energy Product | Density | recoil permeability | Temperature Coefficient | Max Working Temperature | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | αBr | αHcj | ℃(L/D=0.7) | ||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | %/℃ | %/℃ | |||

| G-56M | 1.50 | 1.46 | 15.0 | 14.6 | 1035 | 14 | 995 | 12.5 | 446 | 406 | 56 | 51 | 7.50 | 1.05 | -0.12 | -0.68 | 100 |

| GC-52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1059 | 13.3 | 422 | 382 | 53 | 48 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| GC-50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.05 | -0.12 | -0.66 | 120 |

| G-54SH | 1.49 | 1.44 | 14.9 | 14.4 | 1592 | 20 | 1075 | 13.5 | 438 | 398 | 55 | 50 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| G-52SH | 1.46 | 1.42 | 14.6 | 14.2 | 1592 | 20 | 1059 | 13.3 | 422 | 390 | 53 | 49 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| GC-50SH | 1.42 | 1.39 | 14.2 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| G/GC-48SH | 1.40 | 1.36 | 14.0 | 13.6 | 1592 | 20 | 1035 | 13.0 | 390 | 358 | 49 | 45 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| G/GC-45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| GC-42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 955 | 12.0 | 342 | 318 | 43 | 40 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| GC-40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 939 | 11.8 | 326 | 302 | 41 | 38 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| GC-38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| GC-35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 876 | 11.0 | 287 | 263 | 36 | 33 | 7.50 | 1.04 | -0.115 | -0.56 | 150 |

| G-52SHT | 1.46 | 1.42 | 14.6 | 14.2 | 1751 | 22 | 1059 | 13.3 | 422 | 390 | 53 | 49 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| G/GC-50SHT | 1.42 | 1.39 | 14.2 | 13.9 | 1751 | 22 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| G/GC-48SHT | 1.40 | 1.36 | 14 | 13.6 | 1751 | 22 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| G/GC-45SHT | 1.37 | 1.32 | 13.7 | 13.2 | 1751 | 22 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| GC-42SHT | 1.32 | 1.28 | 13.2 | 12.8 | 1751 | 22 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| GC-40SHT | 1.28 | 1.25 | 12.8 | 12.5 | 1751 | 22 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| GC-38SHT | 1.25 | 1.22 | 12.5 | 12.2 | 1751 | 22 | 923 | 11.6 | 310 | 287 | 39 | 36 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| GC-35SHT | 1.22 | 1.17 | 12.2 | 11.7 | 1751 | 22 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.50 | 1.04 | -0.115 | -0.53 | 160 |

| G-54UH | 1.47 | 1.44 | 14.7 | 14.4 | 1990 | 25 | 1092 | 13.7 | 430 | 408 | 54 | 51 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G-52UH | 1.44 | 1.42 | 14.6 | 14.2 | 1990 | 25 | 1059 | 13.3 | 414 | 390 | 52 | 49 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G-50UH | 1.42 | 1.39 | 14.2 | 13.9 | 1990 | 25 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G-48UH | 1.40 | 1.36 | 14.0 | 13.6 | 1990 | 25 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G-45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G/GC-30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.11 | -0.50 | 180 |

| G-50UHT | 1.42 | 1.39 | 14.2 | 13.9 | 2149 | 27 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-48UHT | 1.40 | 1.36 | 14.0 | 13.6 | 2149 | 27 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-45UHT | 1.36 | 1.32 | 13.6 | 13.2 | 2149 | 27 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-42UHT | 1.32 | 1.28 | 13.2 | 12.8 | 2149 | 27 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-40UHT | 1.28 | 1.25 | 12.8 | 12.5 | 2149 | 27 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-38UHT | 1.25 | 1.22 | 12.5 | 12.2 | 2149 | 27 | 923 | 11.6 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-35UHT | 1.22 | 1.17 | 12.2 | 11.7 | 2149 | 27 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-33UHT | 1.17 | 1.13 | 11.7 | 11.3 | 2149 | 27 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-30UHT | 1.13 | 1.08 | 11.3 | 10.8 | 2149 | 27 | 852 | 10.7 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.11 | -0.48 | 190 |

| G-50EH | 1.42 | 1.39 | 14.2 | 13.9 | 2308 | 29 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-48EH | 1.40 | 1.36 | 14 | 13.5 | 2308 | 29 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-45EH | 13.6 | 13.2 | 13.6 | 13.2 | 2388 | 30 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.45 | 200 |

| G-48EHT | 1.40 | 1.36 | 14 | 13.5 | 2547 | 32 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-45EHT | 1.36 | 1.32 | 13.6 | 13.2 | 2547 | 32 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-42ETH | 1.32 | 1.28 | 13.2 | 12.8 | 2547 | 32 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-40EHT | 1.28 | 1.25 | 12.8 | 12.5 | 2547 | 32 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-38EHT | 1.25 | 1.22 | 12.5 | 12.2 | 2547 | 32 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-35EHT | 1.22 | 1.17 | 12.2 | 11.7 | 2547 | 32 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-33EHT | 1.17 | 1.13 | 11.7 | 11.3 | 2547 | 32 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-30EHT | 1.13 | 1.08 | 11.3 | 10.8 | 2547 | 32 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.45 | 210 |

| G-45AH | 1.36 | 1.32 | 13.6 | 13.2 | 2640 | 33 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-42AH | 1.32 | 1.28 | 13.2 | 12.8 | 2706 | 34 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-40AH | 1.28 | 1.25 | 12.8 | 12.5 | 2786 | 35 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-35AH | 1.20 | 1.17 | 12.0 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-28AH | 1.09 | 1.02 | 10.9 | 10.2 | 2786 | 35 | 772 | 9.7 | 231 | 199 | 29 | 25 | 7.60 | 1.03 | -0.10 | -0.45 | 230 |

| G-38TH | 1.25 | 1.22 | 12.5 | 12.2 | 3182 | 40 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

| G-35TH | 1.22 | 1.17 | 12.2 | 11.7 | 3182 | 40 | 867 | 10.9 | 287 | 263 | 36 | 33 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

| G-33TH | 1.17 | 1.11 | 11.7 | 11.1 | 3182 | 40 | 851 | 10.7 | 271 | 239 | 34 | 31 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

| G-30TH | 1.13 | 1.08 | 11.3 | 10.8 | 3182 | 40 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.60 | 1.03 | -0.10 | -0.42 | 250 |

Note:Temperature Coefficient calucalated by temperature range:Hcj<20kOe,ΔT:20-100℃;Hcj≥20kOe,ΔT:20-150℃,Please contact our sales staff for more demagnetization curve.

| Coating Abbreviation | Environmental Protection | Cost | Color |

Coating Thickness (μm) |

Neutral Salt Spray Test | Humidity Heat Test | PCT Test |

Recommended Application Temperature (℃) |

Surface Tension |

|---|---|---|---|---|---|---|---|---|---|

| Ni | ☆☆☆☆ | ☆☆☆☆☆ | Bright Silver | 5-20 | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ≤260 | 36 |

| Ni | ☆☆☆☆ | ☆☆☆☆☆☆ | Bright Silver | 5-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ||

| Zn | ☆☆☆ | ☆☆☆ | Blue & White | 4-15 | ☆☆☆☆ | ☆☆☆ | ☆☆☆ | ≤160 | 38 |

| Zn | ☆☆☆ | ☆☆☆☆ | Blue & White | 4-15 | ☆☆☆ | ☆☆☆ | ☆☆☆ | ||

| Color Zn | ☆☆☆ | ☆☆☆ | Bright Color | 4-15 | ☆☆☆ | ☆☆☆ | ☆☆☆ | ||

| Color Zn | ☆☆☆ | ☆☆☆☆ | Bright Color | 4-15 | ☆☆☆ | ☆☆☆ | ☆☆☆ | ||

| Ni+Chemical Ni | ☆☆☆☆ | ☆☆☆☆☆☆☆ | Dark Silver | 3-20 | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆ | ≤200 | 36 |

| Ni+Chemical Ni | ☆☆☆☆ | ☆☆☆☆☆☆☆ | Dark Silver | 3-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆ | ||

| Ni+Cr | ☆☆☆ | ☆☆☆☆☆☆ | Dark Black | 5-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ≤260 | 36 |

| Teflon | ☆☆☆ | ☆☆☆☆ | Dark Grey | 15-65 | ☆☆☆ | ☆☆☆ | ☆☆☆ | ≤260 | 36 |

| Ni+Black Ni | ☆☆☆☆ | ☆☆☆☆☆☆ | Black | 5-20 | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ||

| Ni+Sn | ☆☆☆☆ | ☆☆☆☆☆☆ | Bright Silver | 5-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | - | 36 |

| Ni+Ag | ☆☆☆☆ | ☆☆☆☆☆☆ | Silver | 5-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | - | 36 |

| Ni+Au | ☆☆☆☆ | ☆☆☆☆☆☆☆ | Golden | 5-20 | ☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | - | 36 |

| EPOXY | ☆☆☆☆☆☆☆ | ☆☆☆ | Black | 15-65 | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆ | ≤160 | 36 |

| NiCuNi/NiCu+EPOXY | ☆☆☆☆ | ☆☆☆☆☆☆☆ | Black | 25-65 | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆ | ≤160 | 36 |

|

Phosphated |

☆☆☆☆ | ☆☆ | Dark Grey | 1-3 | — | ☆ | ☆ | ≤240 | 37 |

| Nano coating | ☆☆☆☆☆☆☆ | ☆☆☆☆☆ | Light Gray/Black | 15-65 | ☆☆☆☆☆☆☆ | ☆☆☆☆☆☆ | ☆☆☆☆☆☆☆ | ≤300 | ≥38(Plasma Treatment) |

1. SST Environment: 35±2℃,5%NaCl,PH=6.5-7.2,Salt spray sinking 1.5ml/Hr.

2. PCT Environment: 120±3℃,2-2.4atm, distilled water PH=6.7-7.2 , 100%RH

Please contact us for any special requests

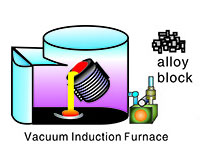

Raw material preparing

Raw material preparing

Melting

Melting

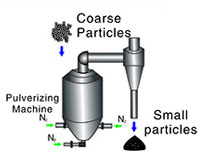

Jet milling

Jet milling

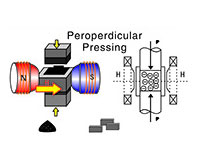

Molding

Molding

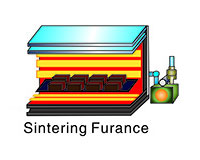

Sintering

Sintering

Magnetizing and packing

Magnetizing and packing

Coating

Coating

Machining

Machining

Magnet property inspecting

Magnet property inspecting

7.4-7.7g/cm3

600-620HV

250-450MPa

1000-1200Mpa

┴C Axle 300 -350MPa

‖C Axle 200-220MPa

2-10KJ/m2

5Mpam1/2

150-160GPa

5-6W·m-1·K-1

0.44J·g-1·K-1

1.25Ω·mm2/m

We would provide you more about our company and work with you to solve the most demanding magnet performance challenges. In case of any questions, please feel free to get in contact with us via telephone or E-mail.